AN OVERVIEW OF DIFFUSION IN RELATION TO AIRTIGHT DEVELOPMENT AND BUILDING DESIGN

- Mary Bon RIBA

- Oct 29, 2015

- 4 min read

Who needs to know about diffusion?

All those involved in the creation of airtight building envelopes, particularly developers, professional designers, specifiers and contractors should be equipped with some basic knowledge on diffusion. It is particularly relevant for those involved in large-scale projects. Confusing diffusion with convection could lead to costly construction errors, to the detriment of both occupant health and comfort as well as the environment. The purpose here is to shed light on the subject in a clear and concise way to avoid such undesirable consequences.

What is diffusion and what causes it?

Convection is a combination of advection and diffusion. Advection is the large-scale motion of a body, be it a gas or vapour, in currents due to air pressure differences whereas diffusion is just the small-scale movement of particles. In an airtight structure, insulation particles, mold spores and pollen will not be conveyed through it. If there is more vapour on one side of a solid material than on another it can diffuse through the surface until concentrations are the same on both sides and cause condensation. If it is present in the same concentration on both sides of a solid material, concentrations will remain equal and unchanged. Convection was explained further in an earlier post.

The principle of diffusion

Where and when can diffusion processes occur?

Diffusion processes can occur in all areas of a structure’s envelope, particularly in its cavities, where gas or vapour moves from areas of high concentration to those of low concentration.

If the overall airtightness of a building is inadequate, more condensation can occur in building components due to moist air flows through roofs, ceilings and walls, than in areas where condensation is caused by diffusion alone.

Instances where diffusion (and condensation) may occur include where

timber or insulation becomes damp due to flanking diffusion through a membrane or air leakage through convection.

materials used in a building envelope are ineffective in controlling air infiltration and exfiltration due to cracks or their high permeance to air.

there is sheathing on unventilated flat, low slope roofs between insulation and an exterior membrane (such as watertight bitumen membrane and wood sheathing).

Why is understanding diffusion important in airtight building envelope design?

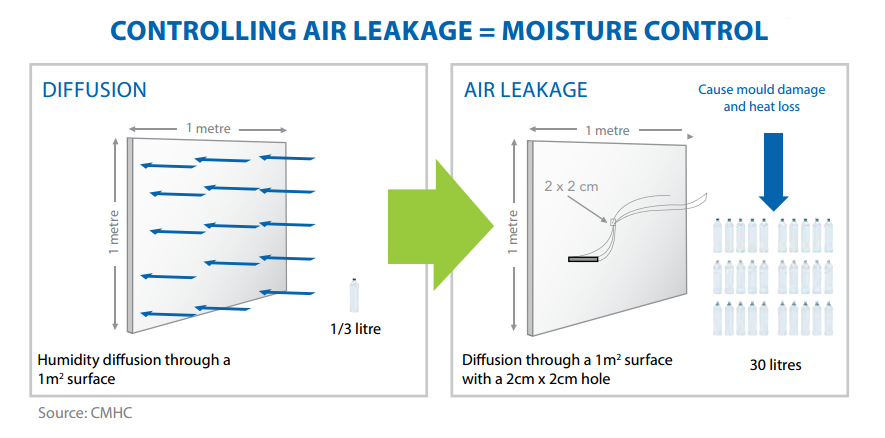

Diffusion is slow, so much so that the quantity of pollutants and moisture that travel through walls (and floors, and ceilings) caused by it is insignificant in contrast to that of air leakage caused by convection.

Typically 99% of the moisture and pollution travels through holes in the structure through convection and only 1% of the moisture and pollution travels because of diffusion.

By sealing all holes of a new airtight building, 99% airtightness is achieved. This highlights how important it is instead to seal gaps with joint sealing tape or expanding foam tape to minimize the negative impact of air leakage.

The significance of diffusion-v-air leakage (convection).

How can diffusion be retarded and the risk of condensation from it be minimised?

Diffusion retarder, or air-pressure retarder materials, can be used to combat condensation from diffusion. If a material only allows for a slow rate of diffusion, it is said to be a diffusion retarder.

Although diffusion ratings are different for different gases, a low perm rating for water vapour generally also means a low gas-diffusion rate.

An interior vapour barrier with a high resistance factor can be used or else low perm rated primers applied according to the situation.

Existing Construction

When used in an existing structure, a paint with a low perm rating is usually sufficient to minimize diffusion.

Many manufacturers have primers that function as diffusion retarders but one thing to watch out for is that they often contain styrene butadiene, also used in carpet backings, which is suspected of causing health problems.

However researchers have shown that the following do not count as air barrier materials without such primer coatings:

Asphalt impregnated felt (15 / 30 lb)

Batt or semi-rigid fibrous insulation

Cellulose spray-on insulation

Expanded polystyrene

Perforated house wraps

Plain or asphalt-impregnated fiberboard

Tongue and groove timber boards

Uncoated concrete block

Vermiculite insulation

However with a good air-pressure retarder, most ordinary paints with average perm ratings have a low enough rating to prevent most diffusion. As will be seen later low perm primers may not even be necessary at all. Instead joint sealing tape or expanding foam tape become the products to focus on.

New Construction In new construction, several common materials function well as diffusion or air pressure retarders including asphalt-impregnated paper on fiberglass insulation, polyethylene sheeting and foil-backed drywall.

An air-pressure retarder should be as tight as possible because it is the primary line of defense at reducing moisture and pollutant transfer through walls. On the other hand as diffusion is such an insignificant factor, a diffusion retarder can be imperfect. If polyethylene sheeting is used as a diffusion retarder and standard drywall as an air pressure retarder, drywall should be sealed.

However It does not need to be sealed particularly tightly unless it is used as both a diffusion retarder and an air pressure retarder, when it should be securely taped and well sealed with joint sealing tape or expanding foam tape whereever there could be air movement through or around it.

Vapour diffusion of individual layers (insulation, plaster and the like) increases towards the outside when no air barrier is fitted.

As a rule of thumb outer layers should show up to 10 times greater vapour diffusion than inner layers.

Vapour barrier in construction (shown in blue)

It is worth noting that some experts believe that, if all gaps are sealed with appropriate tape, diffusion and perm ratings can even be ignored!

Note that when referring to air movement blocking the word barrier is being replaced with the word retarder. So, the more correct terminology and product to use to counter diffusion is an air retarder (or air flow retarder or air pressure retarder) and diffusion retarder rather than an air barrier, or the earlier air/moisture retarders and air/vapour retarders.

Comments